Produktinformation

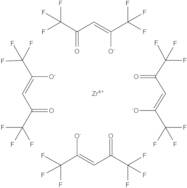

- Zirconium(Iv) Hexafluoro-2,4-Pentanedionate

- Zirconium(Iv)Hexafluoroacetylacetonate

- Zirconium Hexafluoropentanedionate

- Zirconium(lV) hexafluoroacetylacetonate

- Zirconium Hexafluoroacetonylacetonate

- Zirconium hexafluoroacetylacetonate 98%

- Zirconiumhexafluoroacetylacetonate98%

- 1,1,1,5,5,5-Hexafluoropentane-2,4-Dione - Zirconium (4:1)

CVD Material

The growth of thin films via chemical vapor deposition (CVD) is an industrially significant process with a wide array of applications, notably in microelectronic device fabrication. A volatilized precursor (such as a silane, organometallic or metal coordination complex) is passed over a heated substrate. Thermal decomposition of the precursor produces a thin-film deposit, and ideally, the ligands associated with the precursor are cleanly lost to the gas phase as reaction products. Compared to other thin-film production techniques, CVD offers several significant advantages, most notably the potential for effecting selective deposition and lower processing temperatures. Many metal CVD depositions are autocatalytic. Growth of such thin films is characterized by an induction period, which is a consequence of the higher barriers that relate to the activation of the precursor on a non-native substrate. CVD is the preferred deposition method for fabricating optical storage, as it is a well-established method with good scalability, reproducibility, and uniformity. It is also capable of high rates and good composition control.

Zirconium hexafluoro-2,4-pentanedionate; Zirconium hexafluoroacetylacetonate

Soluble: pentaneEmployed in the production of ZrF4 glass coatings by Plasma-enhanced chemical vapor deposition (PECVD)