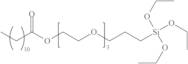

TRIETHOXYSILYLPROPOXY(POLYETHYLENEOXY)DODECANOATE, tech

CAS: 1041420-54-5

Ref. 3H-SIT8186.3

| 25g | Ausgelaufen | ||

| 2kg | Ausgelaufen | ||

| 100g | Ausgelaufen |

Produktinformation

- TRIETHOXYSILYLPROPOXY(POLYETHYLENEOXY)DODECANOATE,tech-95

- Poly(oxy-1,2-ethanediyl), α-(1-oxododecyl)-ω-[3-(triethoxysilyl)propoxy]-

Ester Functional Trialkoxy Silane

Silane coupling agents have the ability to form a durable bond between organic and inorganic materials to generate desired heterogeneous environments or to incorporate the bulk properties of different phases into a uniform composite structure. The general formula has two classes of functionality. The hydrolyzable group forms stable condensation products with siliceous surfaces and other oxides such as those of aluminum, zirconium, tin, titanium, and nickel. The organofunctional group alters the wetting or adhesion characteristics of the substrate, utilizes the substrate to catalyze chemical transformations at the heterogeneous interface, orders the interfacial region, or modifies its partition characteristics, and significantly effects the covalent bond between organic and inorganic materials.

Hydrophilic Silane - Polar - Hydrogen Bonding

Aliphatic, fluorinated aliphatic or substituted aromatic hydrocarbon substituents are the hydrophobic entities which enable silanes to induce surface hydrophobicity. The organic substitution of the silane must be non-polar. The hydrophobic effect of the organic substitution can be related to the free energy of transfer of hydrocarbon molecules from an aqueous phase to a homogeneous hydrocarbon phase. A successful hydrophobic coating must eliminate or mitigate hydrogen bonding and shield polar surfaces from interaction with water by creating a non-polar interphase. Although silane and silicone derived coatings are in general the most hydrophobic, they maintain a high degree of permeability to water vapor. This allows coatings to breathe and reduce deterioration at the coating interface associated with entrapped water. Since ions are not transported through non-polar silane and silicone coatings, they offer protection to composite structures ranging from pigmented coatings to rebar reinforced concrete. A selection guide for hydrophobic silanes can be found on pages 22-31 of the Hydrophobicity, Hydrophilicity and Silane Surface Modification brochure.

Triethoxysilylpropoxy(polyethyleneoxy)dodecanoate; Poly(oxy-1,2-ethanediyl)-α-(1-oxododecyl)-ω-[(3-triethoxysilyl)propoxy]

PEO, Triethoxysilane termination utilized for hydrophilic surface modificationPEGylation reagentHydrogen bonding hydrophilic silaneEmbedded PEG Silane (536.82 g/mol)Provides embedded hydrophilicity with oleophilic compatibilitySurface treatments stabilize particle dispersionsTreated surface contact angle, water: 6-12°Treated surface contact angle, 2-ethylhexyl palmitate: < 15°