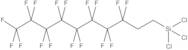

(HEPTADECAFLUORO-1,1,2,2-TETRAHYDRODECYL)TRICHLOROSILANE

CAS: 78560-44-8

Ref. 3H-SIH5841.0

| 5g | To inquire | ||

| 25g | To inquire | ||

| 2kg | To inquire | ||

| 500g | To inquire |

Product Information

- PERFLUORODECYL-1H,1H,2H,2H-TRICHLOROSILANE, FDTS

- (1,1,2,2-Tetrahydroperfluorodecyl)trichlorosilane

- (1H,1H,2H,2H-Heptadecafluorodecyl)trichlorosilane

- (Heptadecafluoro-1,1,2,2-tetrahydradecyl)trichlorosilane

- (Heptadecafluoro-1,1,2,2-tetrahydrodecyl)trichlorosilane

- (Perfluorooctylethyl)trichlorosilane

- 3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-Heptadecafluorodecyltrichlorosilane

- FDTS~Trichloro-1H,1H,2H,2H-perfluorodecylsilane

- Fc 10

- Gelest SIH 5841.0

- See more synonyms

- Heptadecafluoro-1,1,2,2-tetrahydrooctyltrichlorosilane

- Hftcs

- Ks 3175

- Perfluorodecyltrichlorosilane

- SG-Si 191

- Sih 5841.0

- Silane, trichloro(3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyl)-

- Trichloro(1H,1H,2H,2H-perfluorodecyl)silane

- Trichloro(3,3,4,4,5,5,6,6,7,7,8,8,9,9,10,10,10-heptadecafluorodecyl)silane

- Tsl 8232

- [2-(Perfluorooctyl)ethyl]trichlorosilane

ALD Material

Atomic layer deposition (ALD) is a chemically self-limiting deposition technique that is based on the sequential use of a gaseous chemical process. A thin film (as fine as -0.1 Å per cycle) results from repeating the deposition sequence as many times as needed to reach a certain thickness. The major characteristic of the films is the resulting conformality and the controlled deposition manner. Precursor selection is key in ALD processes, namely finding molecules which will have enough reactivity to produce the desired films yet are stable enough to be handled and safely delivered to the reaction chamber.

Fluorinated Alkyl Silane - Conventional Surface Bonding

Aliphatic, fluorinated aliphatic or substituted aromatic hydrocarbon substituents are the hydrophobic entities which enable silanes to induce surface hydrophobicity. The organic substitution of the silane must be non-polar. The hydrophobic effect of the organic substitution can be related to the free energy of transfer of hydrocarbon molecules from an aqueous phase to a homogeneous hydrocarbon phase. A successful hydrophobic coating must eliminate or mitigate hydrogen bonding and shield polar surfaces from interaction with water by creating a non-polar interphase. Although silane and silicone derived coatings are in general the most hydrophobic, they maintain a high degree of permeability to water vapor. This allows coatings to breathe and reduce deterioration at the coating interface associated with entrapped water. Since ions are not transported through non-polar silane and silicone coatings, they offer protection to composite structures ranging from pigmented coatings to rebar reinforced concrete. A selection guide for hydrophobic silanes can be found on pages 22-31 of the Hydrophobicity, Hydrophilicity and Silane Surface Modification brochure. A selection guide for hydrophobic silanes can be found on pages 22-31 of the Hydrophobicity, Hydrophilicity and Silane Surface Modification brochure.

Heptadecafluoro-1,1,2,2-tetrahydrodecyltrichlorosilane; Perfluorodecyl-1H,1H,2H,2H-trichlorosilane; (1H,1H,2H,2H-perfluorodecyl)trichlorosilane; FDTS

Packaged over copper powderγc of treated surfaces: 12 mN/m

Chemical properties

Technical inquiry about: 3H-SIH5841.0 (HEPTADECAFLUORO-1,1,2,2-TETRAHYDRODECYL)TRICHLOROSILANE

If you want to request a quotation or place an order, please instead add the desired products to your cart and then request a quotation or order from the cart. It is faster, cheaper, and you will be able to benefit from the available discounts and other advantages.